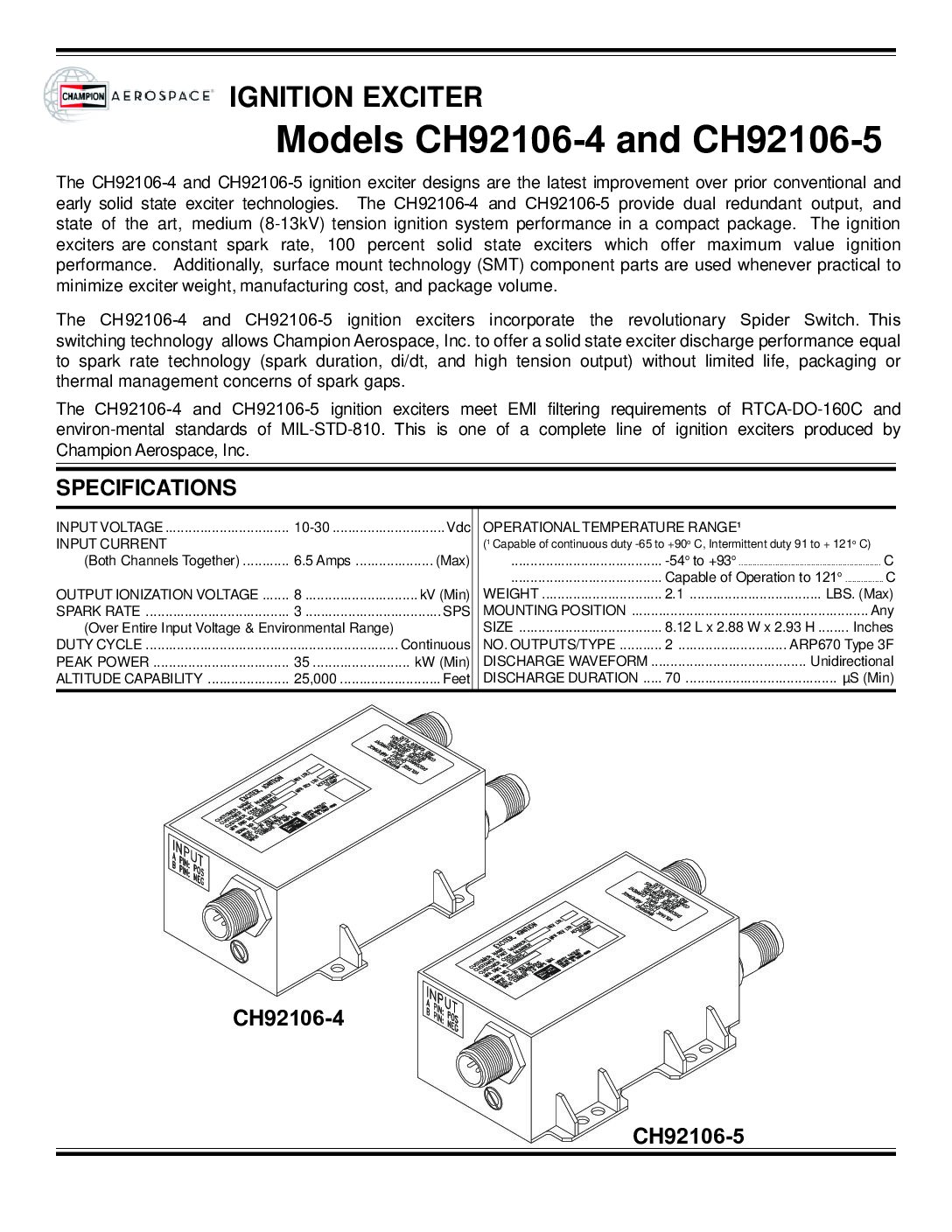

Champion Aerospace manufactures a broad range of high-performance inductive or capacitive discharge ignition exciters in configurable, customer driven designs. Compared to automotive or aviation reciprocating ignition systems, the spark energy discharge of a turbine ignition system is significantly larger- In some cases, the spark is over 100 times higher energy than the spark in an automobile or aviation reciprocating engine.

Champion offers traditional spark gap technology in legacy products, but has transitioned to pioneering designs solely utilizing solid-state technology incorporating our patented multi-voltage “Spider Switch” or new (patent pending) Solid State Spark Gap (S3G) design to maximize reliability, efficiency and capability while minimizing weight. The S3G is a newly introduced concept that is virtually a “plug and play” device into legacy or new applications requiring radiation-free assemblies.

For those customers using radiation bearing exciter designs, note the Champion product is not considered hazardous for use and meets exemptions criteria established by NRC and EURATOM. These exemptions define our exciters are REACH compliant. See Champion Exciter Compliance to NRC-REACH-EURATOM regulatory requirements information paper for further details.

Champion Exciters are widely used in the following aero engine applications:

| Honeywell: | HTF7000*, 131-9 Series, HGT 1700, TPE331, AS907, ALF502, LF507, 331-600 |

| Pratt & Whitney Canada: | PW150*, PW206*, PW307A/B*, PW308A/C/C+*, JT15D, PT6 Series*, PW207*, PW814/815*, APS2300* |

| Pratt & Whitney: | All PurePower® Platforms* |

| Williams: | FJ-44 |

| Rolls-Royce: | Trent 900, Trent 1000, Trent XWB, TP400 |

* Denotes Solid State Configuration

Champion also provides hazardous Location (HAZLOC) certifications with its ignition systems. Champion has a well-established solid state exciter designs that are CSA/ATEX/IECEx certified. These designs can be used as configured or repackaged to meet the any customer specification.

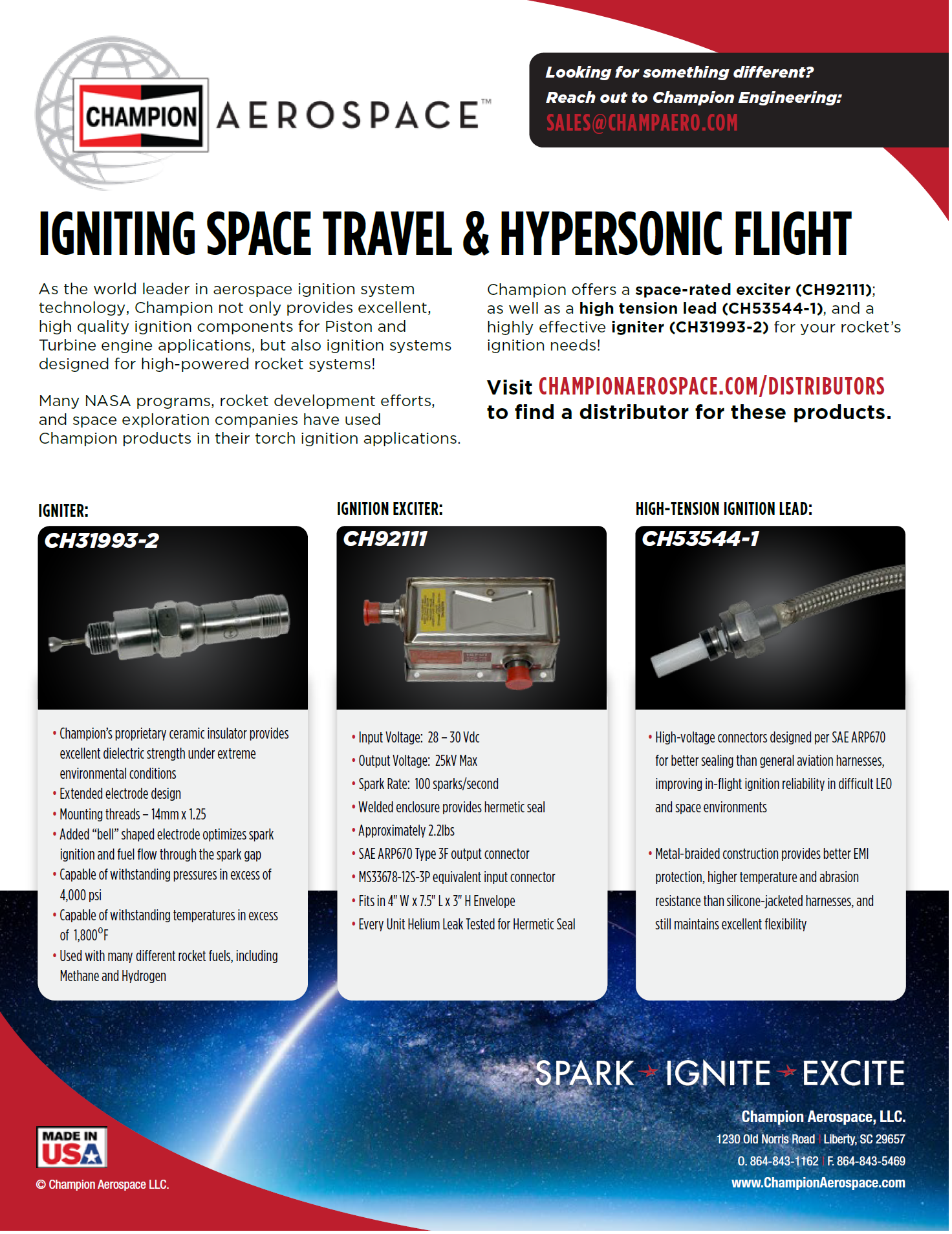

Product Highlight- Pratt & Whitney Canada PT6 Exciter

Champion designed and manufactures the OEM select exciter for the largest turbine fleet in the aerospace industry. The Champion CH92106-1 PT6 exciter, utilizing two fully redundant ignition channels, is able to offer a lighter weight, higher energy, easily reparable and more reliable solution than is offered with the competitor’s exciter. The solid-state switch that discharges the spark event is designed with the latest solid state technology and is not a life limited component like the competitive unit radioactive spark gap.

Champion CH92106-1 exciter benefits include:

- Higher spark rate for reliable starts under all conditions (a 3-spark per second solid state ignition system compared with the current 1-spark per second for 10-381550-4)

- 1.2 joules of energy per second to light the engine (compared to 0.7 joule per second for 10-381550-4)

- Tested in 2009 to the current OEM temperature and vibration requirements

- Non-Radiation bearing exciter; solid state components provide the energy (no spark gap)

- Painted with high temperature paint for corrosion protection

- Un-potted design for improved reparability

The unit has FAA-PMA approval based on Identicality and it carries an OEM part number on the label (3043937-04).

Champion Aerospace manufactures ignition exciters, some of which contain a small amount of radioactive Tritium gas in the high voltage-switching component (referred to in this document as a “Spark Gap”). Spark gaps have been used in turbine engine ignition systems on aircraft since the 1940s, and are simple and reliable high voltage switches. They do require a small dose of radioactive gas in their construction. The fundamental issue is that a radioactive isotope is required to maintain a consistent spark gap ionization voltage over the unit’s operating life. Without the small amount of tritium gas in the spark gap, the ionization voltage of the gap can vary significantly over time and result in a potential decrease in the delivered energy of the exciter. There is no alternative material that Champion can propose for use in our spark gaps that is more benign that Tritium. Competitive comparative spark gaps utilize the less environmentally friendly Kr-85 isotope.

Although the basic elements of every gas turbine ignition system are the same, even the sophisticated observer has trouble delineating amongst the various types. Actual performance, design types, and the physical appearances of most turbine-powered aircraft ignition systems differ from application to application. Engine operational requirements, combustor designs and performance parameters, operating environments, mounting considerations, FAA requirements, and differing design philosophies associated with providing reliable ignition are just a few of the reasons for the many models of turbine engine ignition systems in service today.

Champion Quality and Reliability.

Every Champion Aerospace exciter carries our full warranty and is backed by the Champion name. Our exciters are built to the same exacting standards that have made us a leader in aviation products for over 75 years.

Though more reliable, today’s turbine ignition systems are also more complex, requiring that aircraft technicians possess a higher degree of knowledge and understanding of turbine ignition system theory. Familiarity with a few basics will enable technicians to develop proper insight into standard operation, troubleshooting, and maintenance practices.

Champion offers repair, recertification and overhaul of exciters through our FAA certified repair station. For more information on exciter repairs, please contact your Champion distributor.